|

System nervousness in Material Requirements Planning (MRP) refers to the instability and frequent changes in the MRP system's schedules and plans.

0 Comments

Let's look today at Scrap Rate. Let’s get started. Material Requirements Planning is an essential process in manufacturing, helping companies ensure they have the right materials, in the right quantities, at the right time. One crucial factor that can significantly impact MRP is the scrap rate. So, what exactly is the scrap rate?

A sequential ordering system is a method of assigning unique identifiers to items, transactions, or records in a sequential numerical order. This system is often used in inventory management, manufacturing, and various administrative processes to maintain a clear, straightforward, and easy-to-follow sequence.

A single-level bill of materials is one level of an assembly and does not include any lower-level subassemblies. It displays only one level of components that would be used in their direct parent item.

Strategy is defined as a plan or method chosen to bring about a desired future. Such as; the achievement of a goal, objective, countermeasure or solution to a problem.

Standard work is a detailed definition of the current agreed-upon steps needed for a person to complete one work cycle in the absolute best and most reliable method possible.

Have you ever wanted something to snack on really bad, so you jump up head to the store and when you get there they are fresh out of inventory? Have you ever made the decision to purchase a new vehicle and you go to the dealer and the vehicle you want isn’t there so you go home and order it online? Inventory stock out costs. These are both examples of inventory stock out costs. Stockouts occur when the inventory you have on hand is not enough to fulfill the customers demand needs. Likewise a stock out might be when there is inventory, but the inventory is not what you wanted.

Seasonality is the characteristic of data that is predictable and more often than not can be seen in predictable and repetitive patterns. The patterns can occur: annually (or longer), monthly, weekly, daily, hourly, by the minute, second or less if you can measure it.

Inventory shrinkage occurs when actual inventory levels are less than what is recorded. In general, this means something has gone wrong. Formally defined, inventory shrinkage is the depletion of the actual quantities of inventory that is on hand, in process or in transit. This may be caused by regular reductions, scrap, deterioration or even theft.

Storage costs are another important element of your holding costs. When you think of storage costs you should think of any of the resources that you use to handle and store your inventory. These costs may be direct or indirect money spent on the storage of your goods. Storage costs can include costs for warehousing, warehouse equipment, space, rent, electricity, software, depreciation and warehouse personnel.

Single minute exchange of die is a concept developed by Shigeo Shingo which seeks to perform all setup/changeover times under ten minutes (single minute).

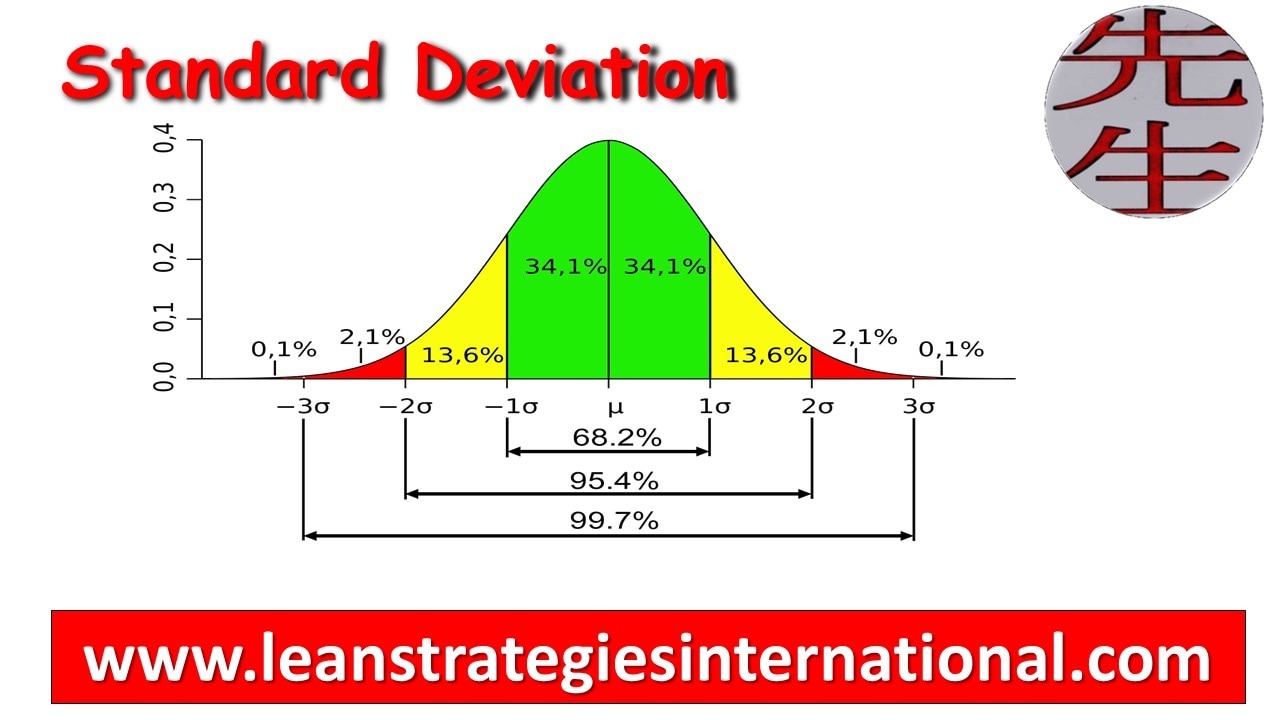

The standard deviation is a statistic that tells you how tight or loose the range/spread of data is in relation to the mean or average of the data. Typically when a data range is clustered tightly the "bell curve" will be tall/steep. When the data is range is spread far apart the "bell" will appear flat or short and wide.

Standard work in process is the minimum necessary level of items or materials needed to maintain the proper flow in a production environment.

The ©STUDY activity was inspired by Mr. Taiichi Ohno's famous stand in the circle training method.

Six Sigma is a strategy that gives organizations a structured means to improve business processes and solve problems. In other words, it is a methodology that uses different improvement tools in an effort to continuously improve business processes. The main focus or intention of Six Sigma is to decrease process variation and improve the quality of products and services. The result of improved business processes leads to increased performance, reduced defects, reduced variation, improved use of capital and resources and more stable and consistent results/outputs.

A spaghetti diagram is a tool used to track the amount of movement or distance traveled by a worker or materials. You can then use a spaghetti diagram to analyze what you tracked and improve the flow. As a tool that is used in the analysis of process flows, a spaghetti diagram reveals redundancy in processes and helps users to identify various forms of waste. The name comes from the reference of laying spaghetti noodles out to show the flow of materials or workers.

Standard costs are actually estimates of the actual costs in a company’s production process. These estimates are used because knowing the exact costs would be impossible until the process is performed. Another way to think of standard costs is as the target or budgeted costs involved in a businesses processes. Standard costs usually include: material costs, labor costs and overhead costs.

The specific identification inventory valuation method is used to track each and every item in your inventory individually. This includes the time it enters the inventory until the time it leaves it. Let’s not get confused here, specific identification is different from LIFO and FIFO. LIFO and FIFO groups pieces of inventory together based on when they were purchased and how much they cost, while specific identification identifies and tracks every piece of inventory individually. The specific inventory method tags or marks each item with its purchase cost and any additional costs that are incurred in the transformation process until it is sold.

Whether it’s materials or information, if the inventory is not there when a customer wants it, chances are they will go somewhere else to find it. Next, revenue is lost and then it gets worse and worse. For example if inventory is not available throughput is decreased, waste is introduced and supply chains slow down. With that being said, many traditional manufacturers and service providers use a type of inventory known as Safety Stock to solve these sometimes catastrophic issues. In this module we will introduce you to Safety Stock.

A subassembly is used to build an assembly. A subassembly is not a component, it is an assembly that is used in a higher level of a bill of materials.

The video above is from Lean Strategies International LLC's Quick Changeover with REDUCE Course. A setup is the work required to change a specific machine, resource, work center or line from making the last good piece of an item to making the first good piece of another item. This includes the preparation and adjustments that are performed until the first good piece is processed.

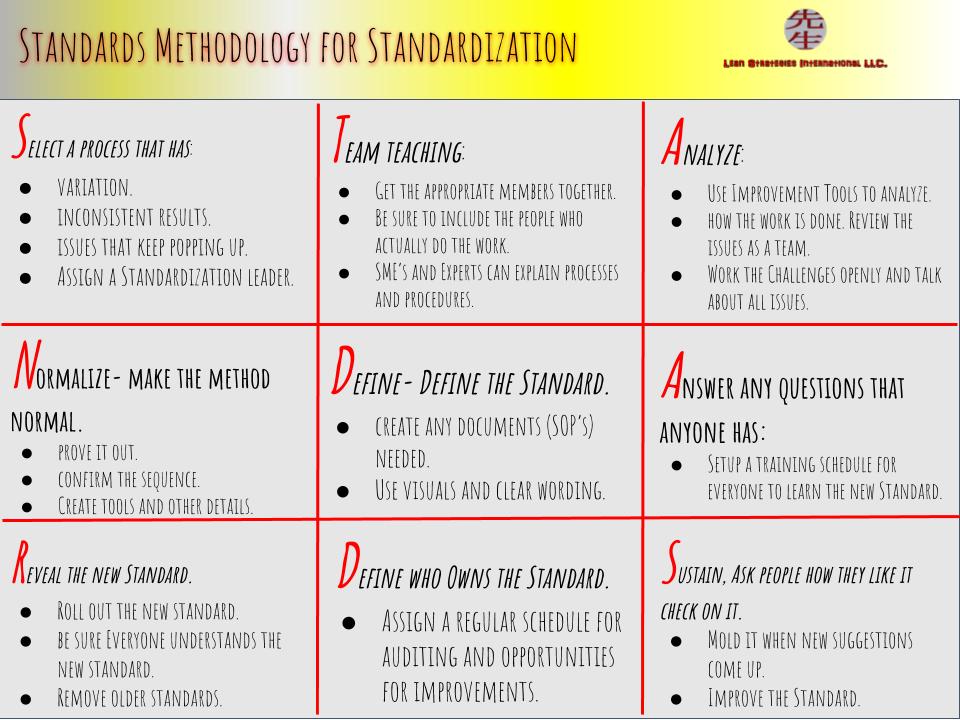

The STANDARDS Methodology is a simple 9 step process that can be used as a method for standardizing.

|

GlossarySubscribe below and receive lean, six sigma, operations, supply chain, logistics, distribution and business terms in your mailbox.

CLICK HERE TO SUBSCRIBE Archives

June 2024

|