|

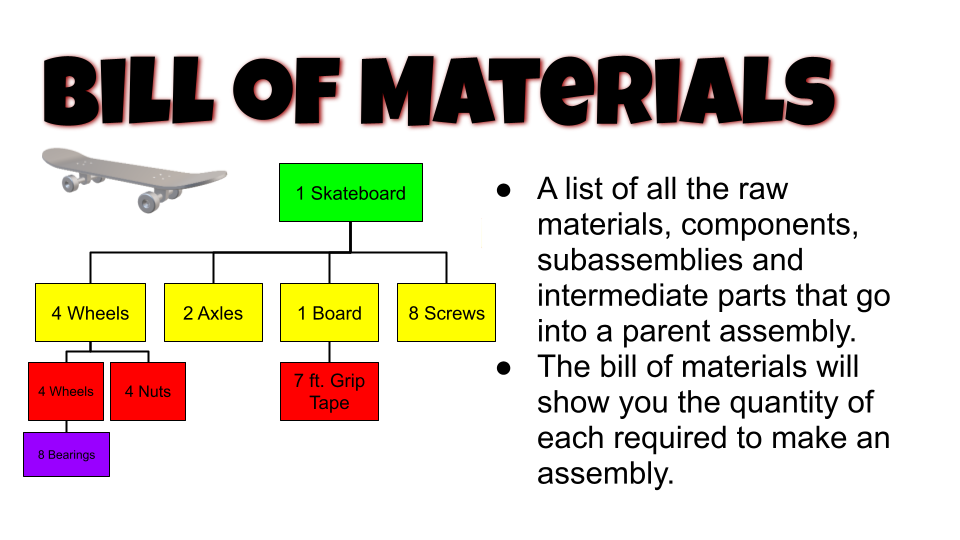

Bills of material are among the most crucial inputs in material requirements planning. There are many different types of bills of material. Establishing, managing your bills of material and keeping them up to date will make building items much more effective. It will prevent defects and help avoid over processing waste. So, what is a bill of materials? A bill of materials or BOM, is a list of all the raw materials, components, subassemblies and intermediate parts that go into a parent assembly. The bill of materials will show you the quantity of each required to make an assembly. For example, a skateboard would need 4 wheels, 1 board, 2 axles and 8 screws on the first level. The bill of materials works with the Master production schedule to determine a time phased plan of requirements that are needed. Purchase reqs, planned orders and suggested releases or production orders are generated. MRP will also generate other notifications, actions and exceptions for planners to act on or consider. There are many different ways that a bill of material is displayed. Some examples are the single-level bill of material, indented bill of material and modular, or, planning bills of material. What is a Bill of Materials Explosion?

References

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

GlossarySubscribe below and receive lean, six sigma, operations, supply chain, logistics, distribution and business terms in your mailbox.

CLICK HERE TO SUBSCRIBE Archives

June 2024

|