|

Father’s Day is a special occasion to honor and celebrate the dads who play an integral role in our lives. This year, let’s take a unique perspective on fatherhood by comparing it to Lean Manufacturing principles. While it might seem unconventional, the parallels between being a great dad and Lean Manufacturing are surprisingly insightful and can highlight the thoughtful, efficient, and impactful ways fathers contribute to their families.

0 Comments

Almost every organization in the world knows by now that the 5S system is an efficient, low maintenance and high impact means of driving continuous improvement. The system itself can be used in offices, shop floors and software systems. So why is it that many who have tried this powerful tool only yield small returns or feel as though something is hiding?

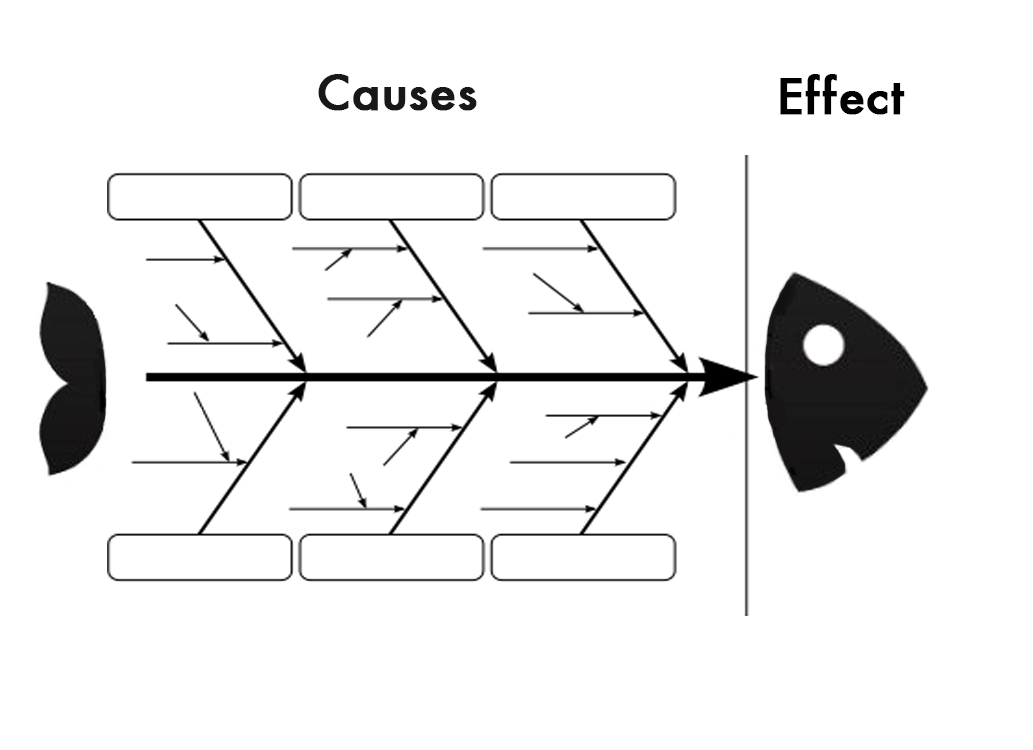

The fishbone diagram, cause and effect, or ishikawa diagram is one of the most common quality tools used today. Best known by its resemblance to a fish's body the fishbone diagram is used to show the many possible causes for an effect. The tool is used to help coordinating brainstorming in an effort to discover root causes.

Happy Holidays everyone! As you start to think about your strategic moves next year also remember to take a look back at the past year and celebrate all the wins.

Twas the night before kaizen when all through the value stream, not a value added activity was flowing not even engineering. Stickies were hung on the wall with great care, In hopes that Lean Strategies International would soon be there.

Lean, Six Sigma and Pull Systems are all great strategies to implement. And, once they are implemented, you need a place, a cave or a headquarters that teams can operate from. Traditionally this place was called a promotion office, lean promotion center or a kaizen office. This centralized location is mainly a place where improvement team meetings can be held and ideas shared.

Many companies use inventory to combat such problems as late deliveries, defects and various other problems. And, while it may help to mitigate these problems, it can also create other problems. You see when companies create inventory buffers to meet customer demand, they tie up cash, take up space and cause inventory to accumulate throughout the production processes as well. There are two distinct strategies that have been used for some time now to combat inventory build up:

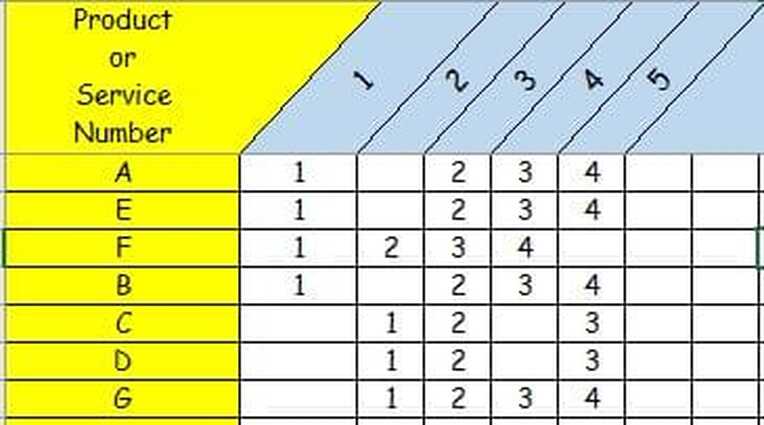

While we all understand how powerful value stream mapping can be, selecting a value stream to begin with can sometimes be a daunting and task. Along with exhausting brainstorming sessions, the effects of product flow can be quite deadly if the "spray and pray" approach is used. Here is a three-step approach for selecting a value stream to map that will put you in a much better position to establish a flow down the line.

The house of Toyota is a perfect representation of a production system being linked together. Each pillar supporting the goals and the entire home resting its weight on a solid foundation. The model has been used for thousands of operating systems over the years and each time the house seems to do the trick more and more effectively. So, what does each of the elements of this house represent in an operating system?

A few months back I received a phone call from an old friend. After we had finished catching up for a bit he began describing to me how he had his employees calculate the yield of his pizza's. each day the employees would mark how much came out and how much was put in. The employee would then divide the out number by the in number giving him the yield percentage. Sound familiar? The method that was being used to calculate yield is known as traditional yield calculation. Out of curiosity I asked him, "what is your yield percentage?" He then shared with me that his yield for each day was always right about 96%. So what was the issue? 96% production rate is not the best, but it's not the worst either. That's when he mentioned that things didn't seem to add up.

Ever since the dawn of time man seeks to make woman happy and keep cave in 5S condition. Bows nice and tidy, dirt floor swept and sanitary with a place in the tunnel to scratch each internal audit. The benefits are almost immediate and the system seems to have a way of energizing the other "tribes." But even with success that dates back to prehistoric times why is it that 5S seems to have become the "beginners" project?

Endless hours of training go by every week on track fields around the world. The teammates are focused on only one thing getting better for competition; Call it passion, maybe desire or even just the want to claim a gold medal most athletes understand that with every event they must continuously improve to become better.

Ever had an annoying fly buzzing around you? You swat and swipe and you just can't get it away from you until you grab the right tool. I certainly have. Much like a fly swatter is the right tool for getting that pesky fly the swot analysis is often times the right tool to help you identify four very important elements of business, projects or venture objectives.

Whether you celebrate Thanksgiving or you're just getting ready for a hearty dinner, planning for the big meal can be quite the task especially if you have lots of guests to provide for. Hours of cooking, ordering and booking travel plans. It's no wonder turkey makes you tired. Allow us if you will to share 5 principles that will keep you lean this thanksgiving.

Many companies wonder, where should I start with my continuous improvement journey? And while the answer varies for everyone, in this post from our soon to be released Just in Time Course we will answer a key question that all organizations must consider, what is the foundation for continuously improving?

This past weekend while attending a Conference in Torrance, California I had the opportunity to network with many wonderful people. It seemed to be a common theme amongst attendants that they either had very little time to conduct Continuous Improvement events or they were focused on Quality. Quality truly is a make all or break all element of any Organization. Whether it is the quality of Information or the quality of a product or service that is produced there is no denying that quality is everyone's responsibility.

All year long we strive for improvements. Squeezing waste from every corner of organizations, Posting new videos, or trying to eliminate that pesky root cause. Whatever it is you do, labor day is for each and everyone of us. Here are some important things to keep in mind on your day off:

From Each and Everyone of Us at Lean Strategies International LLC, we wish you a happy, safe and prosperous fourth of July. May we ever live with gratitude of the great freedoms we have. Celebrate the Fourth of July With Lean Strategies International LLC. with this beautiful medley of patriotic songs.

Submit a post on listen to the gemba and share some of your Supply Chain, Operations or Continuous Improvement knowledge with thousands of visitors. Simply fill out the form below, all articles will be reviewed prior to posting. Upon approval articles will be posted and shared with the community. What does it take to be approved?

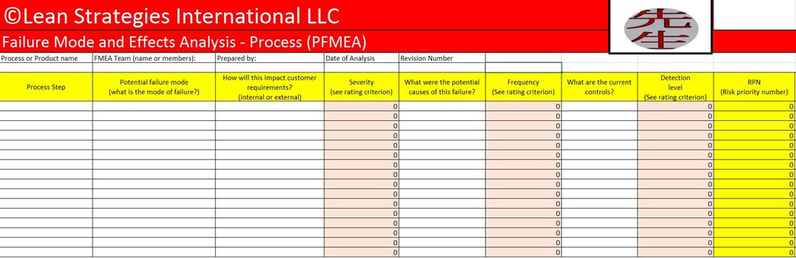

So you have planned out some improvement for an existing process, product or service but you want to ensure that it is a success. One of the best ways to make sure improvement goals are a success is to plan for possible failures. FMEA or failure mode effects analysis will do just that for you. FMEA is a method of identifying possible failures in a process. As the name implies "failure modes" hints that it will help us to understand the possibilities of failure. Sound like a valuable activity? It certainly is, so how is it performed?

Before we get started with an overview of FMEA you need to know that there are a few different FMEA methods. One is for process oriented analysis. You may have heard it referred to as PFMEA. The other type is used in the design or redesign of a process, product or service this type of FMEA is referred to as DFMEA. Today we will not focus on either one specifically. Remember you can find templates here. How to Perform FMEA

In the first three phases of the REDUCE methodology, required data is established, the value stream is engaged for a deeper understanding and internal and external activities are differentiated or separated as defined in the SMED system. The first two phases are largely gathering information and analysis while the second begins to separate tasks and define what can be done while the machine is running and what can be done while the machine is stopped.

The video above is from Lean Strategies International LLC's Quick Changeover with REDUCE Course. Of all the steps in a setup or changeover reduction, separating internal and external activities may in fact be the most important as well as the simplest steps you can take. In the most general sense, performing activities like preparing tools, kits and materials as well as transporting items while your line is running can reduce setup time by as much as 50%.

In this lecture we will discuss the difference between lean thinking and traditional thinking. Let’s recall two of the types of work. Those work activities that add value and those that do not. In the video above we see an activity that is adding value. Value added work has three characteristics to it:

Before improving anything in a setup, we must first consider the current state or common problem areas of what we are improving. In the case of setups, changeovers or turnarounds there are traditionally 4 basic steps where problems and opportunities fall. Those steps are:

|

AuthorClick Here to Submit Your Post on Listen to the Gemba. Archives

June 2024

Categories

All

Recommended Readings |