|

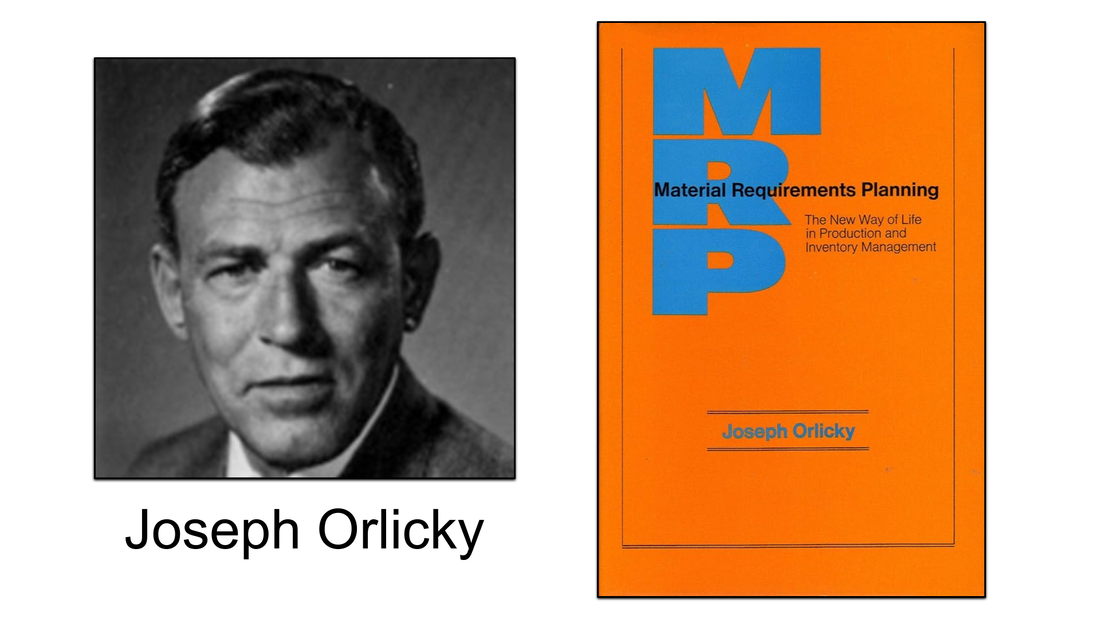

Brilliant minds come along everyday, but few of those minds accomplish that of Joseph Orlicky. Without him, we would have never had MRP, MRP2 or even the modern ERP. When Mr. Orlicky developed the netting algorithm and established the foundational concepts and principles of Material Requirements Planning (MRP), every company relied on different variations of statistical analysis and various reorder point methods. These same companies also carried massive amounts of buffer inventory and safety stock.

0 Comments

Everyday all around the world legends are born. Gurus and Legends are forged in the blink of a moment. The fact is you don't have to write a book to be considered a master of continuous improvement. In fact a guru is defined as an influential teacher or a popular expert by many. With that said each of us have a list of Gurus in the word of supply chain, operations, business or continuous improvement that we look up to. Many of them teaching us skills day in and day out without ever asking for recognition. On this page you can submit those gurus to be featured on the Masters of continuous improvement page. Simply fill out the form below and submit your biography to the community. Genichi Taguchi was an engineer and statistician who was born and raised in the textile town of Tokamachi. He initially studied textile engineering at Kiryu Technical College with the intention of entering the family kimono business. However, with the escalation of World War II in 1942, he was drafted into the Astronomical Department of the Navigation Institute of the Imperial Japanese Navy. After the war, in 1948 Mr. Taguchi joined the Ministry of Public Health and Welfare, where he came under the influence of eminent statistician Matosaburo Masuyama. He also worked at the Institute of Statistical Mathematics during this time and supported experimental work on the production of penicillinat Morinaga Pharmaceuticals, a Morinaga Seika company. Sir Ronald Aylmer Fisher (17 February 1890 – 29 July 1962), was an author who published as R. A. Fisher, he was also a very accomplished English statistician and biologist. Fisher used mathematics to combine Mendelian genetics and natural selection, which ultimately helped to create the new Darwinist synthesis of evolution known as the modern evolutionary synthesis.

Ford Whitman Harris (August 8, 1877 – October 27, 1962) was an American production engineer who is said to have created the economic order quantity. It was derived from the square-root formula and is used to assist in ordering inventory. The economic order quantity has been taught and used all over the world.

Frederick Taylor was a mechanical engineer who pioneered the principles of scientific management. He was passionate about improving efficiency during the late 1800's through the early 1900's. Frederick's efforts in applying engineering principles to factory environments were some of the first to later develop into what we know today as industrial engineering.

Taylor passed the entrance exam for Harvard but did not attend Harvard. Instead of pursuing extended education he chose to become an apprentice patternmaker and a machinist at Enterprise Hydraulic Works in Philadelphia. Eventually Mr. Taylor would complete his apprenticeship and move on to climb the ladder of the Midvale Steel Works. It was here that Fredericks talents would eventually lead him to hold such positions as chief engineer. Sakichi Toyoda is often referred to as the father of Japanese industrial revolution. He is also the founder of Toyota Industries Co., Ltd. He created a variety of weaving device. The most famous invention is the automatic power loom in which he applied the principles of Jidoka (autonomous automation). Jidoka principle, which means that the machine stops itself when the problem occurs, then became part of the Toyota Production System.

Many of the great techniques, philosophies and tools from the past were created out of need. Almost all techniques, philosophies and tools were the result of innovation or newly created. The term history is defined in part as “the study of past events”. In almost every definition of the term “history” we learn that there is in most cases a connection with someone or something. Like any other strategy, lean has some fascinating history behind it. That history helped form shape and innovate the strategy that we know today. Over the next few months this article will be updated to summarize the history of lean and look at some of the significant happening that helped form and shape lean today.

Taiichi Ohno was born in Manchuria, China in 1912 and graduated from Nagoya Institute of Technology in 1932. In 1943 Mr. Ohno joined Toyota as a production supervisor and eventually earned the name as one of the fathers of the Toyota Production System. He wrote many books supporting the Toyota Production System some of which are: Toyota Production System: Beyond Large-Scale Production and Workplace Management.

Born in 1909 Shigeo Shingo would become one of the most influential figures in lean manufacturing. After graduating from Yamanashi technical college Dr. Shingo went to work for the Taipei Railway Company. Shortly after he was transferred to a manufacturing plant in Yokohama by the name of Amano Manufacturing. Dr. Shingo immediately went to work improving production by 100%.

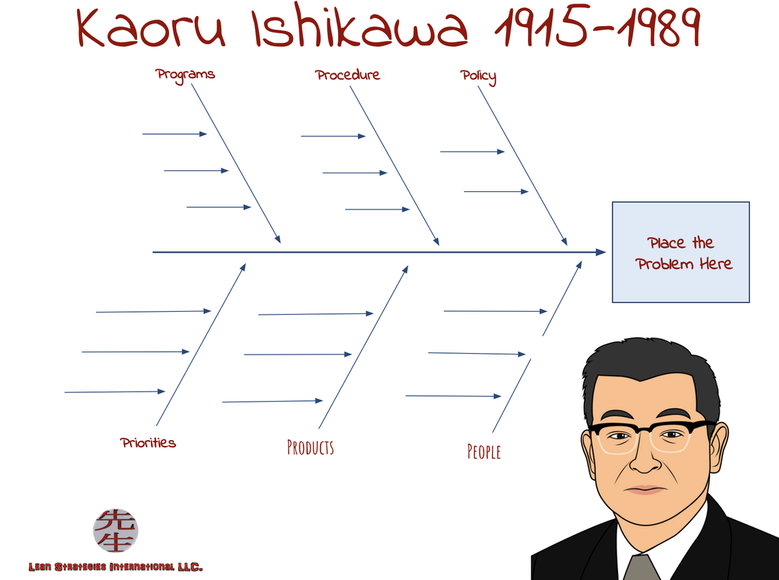

Kaoru Ishikawa is recognized by many as the "master" and father of Quality. If not on a global scale than certainly in his native land of Japan. Kaoru Ishikawa was most noted for the development of the Ishikawa, Cause and Effect or Fishbone diagram, however his impact on quality spread much further than just cause and effect.

Shewhart was the first honorary member of the American Society of Quality. He brought together the disciplines of statistics, engineering, and economics which eventually earned him the right to be known as the father of quality.

In 1945 many quality associations began forming around the world. The benefits and passion surrounding quality and industrial activities were gaining momentum. Almost 40 years earlier, Romania would see the face of one, Joseph Juran. As one of six children Mr. Juran grew up with two sisters who shared his passion for learning. Juran would live first in România and then in Humorului for only a short time before his family would settle in Minneapolis. Here Juran would earn his High School degree from Minneapolis South High School in 1920.

There is not just one thing that Dr. Akao can be noted for. A true advocate of continuous improvement is the best way to sum up Dr. Akao. As the 24'th honorary member of the ASQ, Dr. Akao led many great projects with his development of Quality Function Deployment. Along with QFD, Dr. Akao developed several other methodologies that became normal practices in Japan. While methodologies were not foreign to Dr. Akao he was often found advocating strategic initiatives like Hoshin Kanri worldwide.

Philip Bayard "Phil" Crosby, (June 18, 1926 – August 18, 2001) was a businessman and author who contributed to management, theory and advocated quality in many different ways. Crosby initiated the Zero Defects program at the Martin Company. As the quality control manager of the Pershing missile program, Crosby was credited with a 25 percent reduction in the overall rejection rate and a 30 percent reduction in scrap costs.

Eli Whitney was a famous American inventor in the late 1700’s and early 1800’s. Most people know Mr. Whitney for his invention of the cotton gin. He was born in 1765 and attended Yale University. While his cotton gin invention was in fact revolutionary many people attempted to steal the idea which ultimately led to Mr. Whitney changing his focus to guns and ammunition. At this time muskets required a great deal of manual labor and time to build. To reduce the amount of time and complexity associated with building a musket Mr. Whitney began building interchangeable parts which certainly improved the changeover times and reduced the need for workers to setup and re-setup with each musket. As a result of these interchangeable parts the assembly or assemble to order concept was created. Along with the design of interchangeable parts Mr. Whitney spent a great deal of time studying the motion of workers and people. Mr. Whitney’s drive and passion for improving things then lead to what we know today as time and motion studies. One might guess that even during the industrial revolution many different forms of waste were revealed.

Reference: "Eli Whitney: Father of American Technology - Fast Facts ... - YouTube." 14 Dec. 2015, https://www.youtube.com/watch?v=qyvxFCMShNQ. Accessed 26 Nov. 2018. Professor Jiro Kawakita was a well-known scholar of ethnogeography in Japan. Through his fieldwork and research on the Himalayan Highlanders of Nepal, he has established a distinct methodology in field sciences and revealed the system of the people, culture, way of life and ecology. His achievements are very widely studied and some of the tools he established are still used today, the main one being the affinity diagram which is a tool used within the KJ Method and provides a structured basis for Lean Strategies International LLC’s ©CURE Methodology.

The Following is a great biography borrowed from: Fukuokaprize. Please note there are not many biographies on this pioneer, master of the Affinity diagram which is widely used in project management today. If you have any additional information on this Master, please feel free to share, link and comment in the comments section below. Your name will be cited with the contributions and we would be more than happy to link to a page of yours if you would like. William Edwards Deming (October 14, 1900 – December 20, 1993) was an American engineer, statistician, professor, author, lecturer, and management consultant. Educated initially as an electrical engineer and later specializing in mathematical physics, he helped develop the sampling techniques still used today by the U.S. Department of Census and the Bureau of Labor Statistics. In his book, The New Economics for Industry, Government, and Education, Deming championed the work of Walter Shewhart who used techniques such as:

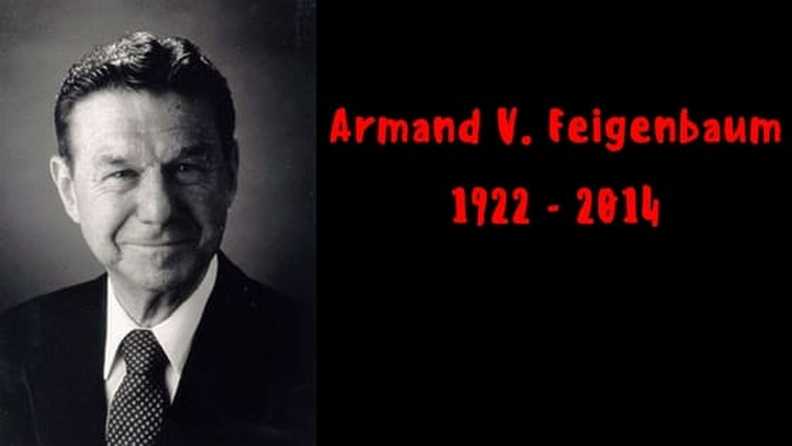

Dr. Feigenbaum was an American quality control guru who specialized in Total Quality Control. Dr. Feigenbaum received his PH.D. in economics from MIT and shortly after was named the director of manufacturing operations at General Electric before moving on to become President and CEO of General Systems Company which was located in Pittsfield Massachusetts. Feigenbaum wrote several books on the topic of Quality Management including: Total Quality Control and The Power of Management Innovation.

Dr. Feigenbaum was best known for his contributions in quality, some of which included:

Reference: Wikipedia: Armand V. Feigenbaum Noriaki Kano is a professor and consultant who specializes in quality management. Mr. Kano is most noted for the phenomenal tool that he developed known as the Kano Model. The Kano model is a customer satisfaction model which places customer preferences into five categories:

Bill Smith is the father of Six Sigma. Mr. Smith was born Bill Smith worked for Motorola in the 1980's where he held positions like vice president and senior quality assurance manager. Mr. Smith was a very accomplished engineer of 35 years before he joined with Motorola. Driven with the spirit of perfection, Bill changed the way statistical analysis was performed. He and Dr. Harry would eventually develop what we know today as the DMAIC methodology.

Dr. Mikel J. Harry received his PHD from Arizona State University in 1984. Dr. Harry is a widely recognized name in Six Sigma. He wrote a book entitled Six Sigma: The Breakthrough Management Strategy Revolutionizing the World's Top Corporations which has been on the best selling books on six sigma for many years now.

Along with over 50 publications on six sigma Dr. Harry's work is used in such organizations as General Electric, Ford Motor Company, Allied Signal and Motorola. Dr. Harry is truly one of the Master's of Six Sigma and has a long list of accomplishments within the industry including: - Development of six sigma quality program for Motorola in 1987. - Winning the Malcolm Aldridge Quality award in 1987. - Founder of Six Sigma Academy - Multiple Global Business awards. For more information on Dr. Mikel Harry visit his biography page. |

Categories

All

|