|

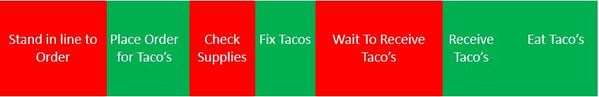

In this week's Series on Value Stream mapping we will look at the What, Why and How of Value Streams. Over the course of this week Lean Strategies International LLC will define what a Value Stream is and how Value Stream Mapping can assist in making the Value Stream more visual and we will talk about some reasons why Value Streams are such a powerful tool to use in any work environment. Finally we will give you one example of how a Value Stream map can be laid out. To Start off we should define what a Value Stream is. A Value Stream includes all the steps both necessary and unnecessary steps that take a product from the early stages of a raw material or service to receiving the cash from the customer. We identify these steps as Value added and Non Value Added steps, this is why it is referred to as a "Value" stream, Some activities in the stream add value others just add waste. There are in essence many different types of Value Stream maps, however the three most common that you will see are the Process Level map, Business or Organizational Map and finally the Extended VSM. A process level map would document activities in a specific department or a defined cell one example may be the way a purchasing department may release a purchase order if all the activities fall under that department it would be safe to say a process level map is appropriate to use. The next type of map that is used is the Business or Organizational Map, these types of maps commonly document activities that require the efforts of multiple departments in an organization. For instance if that same Purchasing process uses the efforts of planning, production, accounting and Program Managers it may be more appropriate to map the value stream with a Business type map sometimes referred to as a 3D VSM or Factory VSM. The final type of Value Stream Map is the Extended VSM, these types of Maps generally show the entire system across multiple organizations. Let's Look at one Example of a Value Stream that may help us to understand the Value Stream a little bit better. You and I are going to eat some Taco's. We will define the Value Stream at the Process level. First- We Stand in Line to Order our Taco's Second- We place our order Third- We wait for them to check that they have everything they need Fourth- They confirm Fifth- They fix the Taco's Sixth- we receive the Taco's and Seventh- we eat the taco's You Can probably tell by this example which activities are value added to a Customer and Which activities are not. When the Value Stream becomes visual we now have a Value Stream Map, which identifies or Map's out the activities performed in the Process. This is a very basic example of a Value Stream map, We are sure that more details could log much more savings, but let's dig a bit deeper here. As you can tell the (Muda) or Non-Value added portion of the Value stream takes up a significant portion of our Taco trip. This is very common in Work environments too, Infact if it's the first time you have documented your value stream it is not uncommon for the Non-Value to be almost 75-80% of your Value Stream. This brings us to our next point What we tend to do is press on the Value Added portion of the Value stream, which not only is what the Customer wants to pay for but often times will yield only seconds in savings (i.e. running machines faster than they can handle, pushing employees, unbalanced workloads) and more often than not yields broken machines or disgruntled employees. But as you can tell if we focus on the Non-Value added portion of the Value Stream and Eliminate waste we can often yield much larger results. Hopefully you are beginning to understand the possibilities and power a Value Stream Map can bring to your Lean Strategy. Tomorrow We will look at some examples of Why you would use a Value Stream map including moving from the Current state to the Future State.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorClick Here to Submit Your Post on Listen to the Gemba. Archives

June 2024

Categories

All

Recommended Readings |